Kerone Designers & Manufacturers

Industrial Heating Equipments & Microwave Heating System, RF Heating System, Vacuum & Infrared Heating Equipments, Coating & Impregnation Plants for paper and fabrics, Process Heaters & Control, Special Purpose Machineries, Flameproof Heating Systems, Fuel Gas Heaters, High Pressure Heating Skids, Control Panels, Customised Heating and Cooling Solutions.

Radio frequency Batch Heating Oven In Radio frequency batch heating Ovens are a heating oven material. That are first and foremost shielded chambers where the material to be heated is placed between the plates or electrodes. As advanced technology is used life of the instrument is more Also they are excellent from the safety point of view. Its properties are unaffected so also mechanical properties. It's have various type of feature. |

|

||||

| Reduced Costs : As moulding cycle time is reduced and accuracy of the task is improved; production becomes less time consuming with more accuracy which means reduced costs & rejections. | |||

|

| Advantage : We have always used Advanced Technology and our products are made to international Standards, and so we are able to provide you with wide range of Rugged and reliable products to choose from so that you get exactly what you wanted. Our products have in built safety circuits for maximized safety of Operator and the Machine. |

How Radio Frequency Heating Works? |

|

|

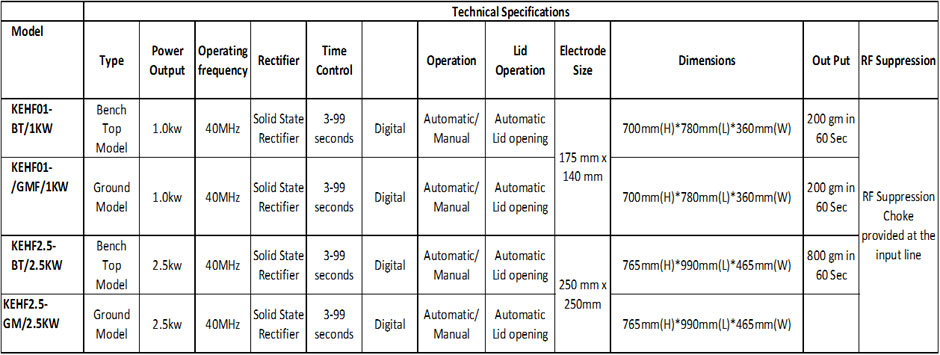

Technical Specifications |

|